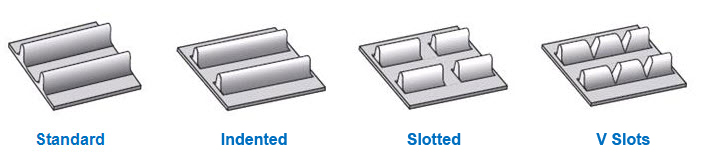

Cleats are usually used to transport goods on an inclined conveyor. Products are retained on the belt and does not accumulate at the foot of the conveyor. Standard cleats are made of PVC. They are heat-sealed onto the belt and can be modified according to the customer needs (indents on the sides, notched in the middle, etc).

Molded rubber cleats

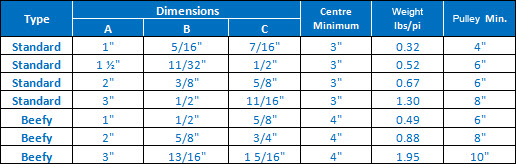

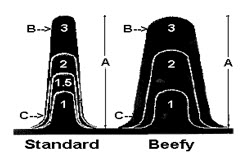

Our only recommended way to operate a conveyor belt with rubber cleats is to use specially molded cleats which withstand rugged applications. Some are applied in cold process on the belt cover, but they do not stand up as well as molded cleats and can often delaminate the belt cover. Following are the dimensions of the standard and Beefy cleats molded into the belt. These cleats can be done through different hardness (ShA) and compounds to accommodate specific needs.

Movable cleats (screwed or bolted)

These cleats types may be installed manually through the belts using specific screws or bolts. These are typically used in the agricultural industry for the transport of goods on inclined conveyors and prevents the rear bearing of the substances carried. Another great advantage of these cleats is that it requires a pulley diameter lower than belts with molded cleats.

Tatch-A-Cleat® Econo-Cleat®

Tatch-A-Cleat® Model L

Tatch-A-Cleat® Model HD

Tatch-A-Peg™/ Tatch-A-Lug®